1. Nxopaxopo wa xivumbeko

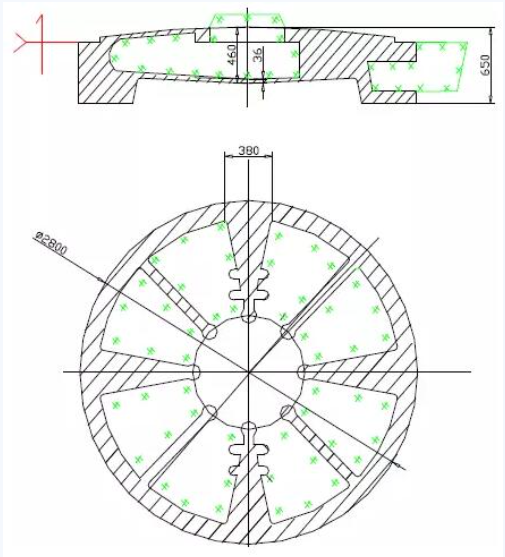

(1) Leswivalve ya phaphataniyi na xivumbeko xa xirhendzevutani xa xivumbeko xa khekhe, xirhendzevutani xa le ndzeni xi hlanganisiwile no seketeriwa hi 8 wa timbanga to tiyisisa, khumbi ra le henhla ra Φ620 ri vulavurisana na xirhendzevutana xa le ndzeni, naswona leswin’wana hinkwaswo swavalveyi pfariwile, xirhendzevutana xa sava swa tika ku xi lunghisa naswona swa olova ku xi onha. Havumbirhi bya ku humesiwa ka moya ni ku basisiwa ka xirhendzevutana xa le ndzeni swi tisa swiphiqo leswikulu, hilaha swi kombisiweke hakona eka Xifaniso 1.

Ku enta ka rirhangu ra ti castings swa hambana swinene, ku enta lokukulu ka rirhangu ku fika eka 380mm, naswona ku enta ka rirhangu ra le hansi i 36mm ntsena. Loko casting yi tiyile, ku hambana ka mahiselo i kukulu, naswona kuhunguteka lokunga ringaniki kunga humesa hiku olova ti shrinkage cavities xikan’we na shrinkage porosity defects, leswinga ta endla leswaku mati ya khuluka eka xikambelo xa hydraulic.

2. Dizayini ya phurosese: .

(1) Vuandlalo byo hambanyisa byi kombisiwile eka Xifaniso 1. Veka makumu hi makhumbi eka bokisi ra le henhla, endla xirhendzevutana xa sandi hinkwaro eka xivandla xa le xikarhi, naswona u lehisa nhloko ya xirhendzevutana hi ndlela leyi faneleke ku olovisa ku bohiwa ka xirhendzevutana xa sava na ku famba ka xirhendzevutana xa sava loko bokisi ri hundzuriwile. Ku tiya, ku leha ka nhloko ya cantilever core ya ti blind holes timbirhi etlhelo swi lehe kutlula ku leha ka hole, leswaku center of gravity ya sand core hinkwayo yi biased kuya etlhelo ka core head kutiyisisa leswaku sand core yitshamisekile naswona yitshamisekile.

Semi-closed pouring system ya amukeriwa, ∑F endzeni: ∑F horizontal: ∑F straight=1:1.5:1.3, sprue yitirhisa ceramic tube leyingana diameter yale ndzeni ya Φ120, naswona swiphemu swimbirhi swa 200×100×40mm refractory bricks swivekiwa ehansi ku sivela nsimbi leyi n’okiweke kuva yinga kongomanga Eka impact sand mold, 150×150×40 foam ceramic filter yi vekiwile ehansi ka runner, naswona 12 wa ti ceramic tubes letingana diameter yale ndzeni ya Φ30 ya tirhisiwa leswaku runner yale ndzeni yihlanganisa hiku ringana ehansi ka casting hiku tirhisa thangi ro hlengeleta mati ehansi ka filter kuva yi endla xikimi xo chela ehansi ka ku chela, tani hileswi swikombisiweke eka Figure 2 Essence

(3) Veka 14 ∮20 wa ti cavity air holes eka xivumbeko xale henhla, veka Φ200 sand core vent hole exikarhi ka nhloko ya core, veka nsimbi yo titimela eka swiphemu swo tiya na leswikulu ku tiyisisa ku tiya loku ringaniseriweke ka casting, naswona tirhisa graphitization expansion principle ku khansela feeding riser yitirhisiwa ku antswisa mbuyelo wa maendlelo. Vukulu bya bokisi ra sandi i 3600×3600×1000/600mm, naswona ri weldiwile hi 25mm yo enta steel plate ku tiyisisa ku tiya loku ringaneleke na ku tiya, tani hileswi swikombisiweke eka xifaniso xa 3.

3. Vulawuri bya maendlelo

(1) Modeling: Before modeling, use a Φ50×50mm standard sample to test the compressive strength of the resin sand ≥ 3.5MPa, and tighten the cold iron and the runner to ensure that the sand mold has sufficient strength to offset the graphite produced when the molten iron solidifies Chemical expansion, and prevent the molten iron from impacting the runner part for a long time ku vanga ku hlantswiwa hi sandi.

Ku endliwa ka core: Nkoka wa sandi wu avanyisiwile hi swiphemu swa 8 leswi ringanaka hi 8 wa timbanga to tiyisisa, leti hlanganisiweke hi xirhendzevutani xa le xikarhi. Akuna swiphemu swin’wana swa nseketelo na exhaust handle ka nhloko ya middle core. Loko sand core yinga tshamisekangi naswona Exhaust, sand core displacement na ti air holes swita humelela endzhaku ko cheriwa. Hikwalaho ka leswi ndhawu hinkwayo ya xirhendzevutana xa sava yi nga yikulu, yi avanyisiwile hi swiphemu swa tsevu. Yifanele kuva na matimba lawa ya ringaneleke xikan’we naku tiya kutiyisisa leswaku core ya sandi ayinga onhaki endzhaku ka ku humesiwa ka mould, naswona ayinga onhaki endzhaku ko cheriwa. Deformation yihumelela, leswaku kuta tiyisisiwa kufana ka wall thickness ya casting. Hi xivangelo lexi, hi endle hi ndlela yo hlawuleka marhambu yo hlawuleka ya core, naswona hi ri bohile eka marhambu ya core hi ntambhu yo nghenisa moya ku koka gasi leyi humaka eka nhloko ya core ku tiyisisa ku hlangana ka xivumbeko xa sandi loko hi endla core. Hilaha swi kombisiweke hakona eka Xifaniso xa 4.

(4) Bokisi ro pfala: Loko hi tekela enhlokweni leswaku swa tika ku basisa sava leri nga endzeni ka valve ya phaphatani, xirhendzevutana hinkwaxo xa sava xi pendiwe hi swiphemu swimbirhi swa pende, leyara yo sungula yi burachiwa hi pende ya zirconium leyi nga ni byala (Baume degree 45-55), naswona leyara yo sungula yi pendiwa yi tlhela yi hisiwa. Endzhaku ko omisiwa, penda leyara ya vumbirhi hi pende ya magnesium leyi endliweke hi byala (Baume degree 35-45) kuva ku sivela casting ku namarhela eka sandi na sintering, leswinga basisiwiki. Xiphemu xa nhloko ya core xi hayekiwile eka phayiphi ya nsimbi ya Φ200 ya xivumbeko lexikulu xa marhambu ya core hi swikwirikiri swinharhu swa M25, swi lulamisiwile no lotleriwa hi bokisi ra sandi ra xivumbeko xa le henhla leri nga na swifunengeto swa swikwirikiri naswona ku kamberiwa loko ku enta ka rirhangu ra xiphemu xin’wana na xin’wana ku fana.

4. Endlelo ro n’oka na ku chela

(1) Tirhisa Benxi low-P, S, Ti ya xiyimo xale henhla xa Q14/16# pig iron, naswona yi chela hi ratio ya 40%~60%; ti trace elements tofana na P, S, Ti, Cr, Pb, etc. ti lawuriwa swinene eka scrap steel, naswona ku hava rust na oyili leswi pfumeleriwaka , ratio yo engetela i 25%~40%; chaji leyi tlheriseriweke yifanele ku basisiwa hiku bulusa hi xibalesa loko yinga se tirhisiwa ku tiyisisa ku basa ka chaji.

(2) Vulawuri bya xiphemu lexikulu endzhaku ka furniture: C: 3.5-3.65%, Si: 2.2%-2.45%, Mn: 0.25%-0.35%, P≤0.05%, S: ≤0.01%, Mg (masalela): 0.035% ~0.05%, ehansi ka xisekelo xo tiyisisa spheroidization, mpimo wa le hansi wa Mg (residual) yifanele ku tekiwa hilaha swinga kotekaka hakona.

(3) Vutshunguri bya spheroidization inoculation: ku tirhisiwa ti spheroidizers ta magnesium yale hansi na ya misava leyi nga tolovelekangiki, naswona ratio yo engetela i 1.0%~1.2%. Ndlela ya ntolovelo yo hlamba vutshunguri bya spheroidization, 0.15% wa ku cheriwa ka nkarhi wun’we swifunengetiwa eka nodulizer ehansi ka phasela, naswona spheroidization yihetisiwile. Kutani slag yi endliwa subcontracted for secondary inoculation ya 0.35%, naswona flow inoculation ya 0.15% yi endliwa hinkarhi wa ku cheriwa.

(5) Endlelo ro hatlisa ro chela ra mahiselo yale hansi ri amukeriwile, mahiselo yo chela i 1320°C ~ 1340°C, naswona nkarhi wo chela i 70 ~ 80s. Nsimbi leyi n’okiweke ayi kavanyetiwi loko ku cheriwa, naswona khapu ya sprue yitshama yirikarhi yitele ku sivela gasi na swilo leswi katsekaka leswaku swinga katseki eka xivumbeko hiku tirhisa runner. xivandla xa xirhendzevutani.

5. Vuyelo bya xikambelo xa ku hoxa

(1) Kambela matimba yo koka ya xibokisana xo kambela lexi hoxiweke: 485MPa, ku leha: 15%, ku tiya ka Brinell HB187.

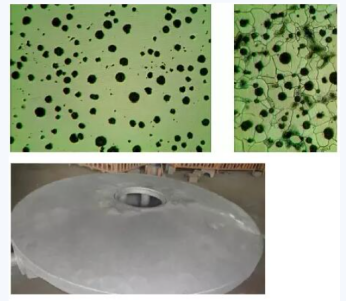

(2) Nhlayo ya spheroidization i 95%, vukulu bya graphite i grade 6, naswona pearlite i 35%. Xivumbeko xa metallographic xi kombisiwile eka Xifaniso xa 5.

(3) Ku hava swihoxo leswi rhekhodiwaka leswi kumiweke eka ku kumiwa ka swihoxo swa vumbirhi swa UT na MT swa swiphemu swa nkoka.

(4) Xivumbeko xa yona i xiphepherhele naswona xi rhetela (vona Xifaniso xa 6), handle ka swihoxo swa ku hoxa swo fana na ku katsa ka sava, ku katsa ka slag, ku pfala ka xirhami, na swin’wana, ku enta ka rirhangu ku fana, naswona swipimelo swi fikelela swilaveko swa swifaniso.

(6) Xikambelo xa ntshikelelo wa hayidiroliki xa 20kg/cm2 endzhaku ka ku lulamisiwa a xi kombisanga ku vupfa

6. Mahetelelo

Kuya hi swihlawulekisi swa xivumbeko xa valve leyi ya phaphatani, xiphiqo xa ku onhaka lokunga tshamisekangiki naku olova ka core leyikulu ya sandi exikarhi naswona ku basisiwa ka sandi loku tikaka swi tlhantlhiwa hiku kandziyisa eka dizayini ya pulani ya maendlelo, vuhumelerisi naku lulamisiwa ka core ya sandi xikan’we naku tirhisiwa ka swifunengeto leswi sekeriweke eka zirconium. Ku vekiwa ka ti vent holes swi papalata ku koteka ka ti pores eka ti castings. Kusuka eka vulawuri bya charge ya furnace na runner system, foam ceramic filter screen na ceramic ingate technology switirhisiwa ku tiyisisa ku basa ka nsimbi leyi n’okiweke. Endzhaku ka vutshunguri byo tala bya inoculation, xivumbeko xa metallographic xa ti castings na to hambana Ku tirha loku heleleke ku fikelele swilaveko swa ntolovelo swa vaxavi

Ku sukaTianjin Tanggu Valava yo pfalela mati Co.,ltd. Valve ya phaphatani, valve ya gede, . Y-xigwitsirisi, wafer valve yo kambela tipuleti timbirhiku endla swilo.

Nkarhi wa poso: Apr-29-2023