I yinivalvecavitation? Xana u nga swi herisa njhani?

Tianjin Tanggu Mati-Xisirhelelo xa Valve Co., Ltd

Tianjin, .CHINA

19th, .Khotavuxika, .2023. Hi lembe ra 2023

Tanihi leswi mpfumawulo wu nga vaka ni vuyelo byo biha emirini wa munhu, tifrekwensi to karhi ti nga tlanga hi khombo eka switirhisiwa swa le tifemeni loko valve yo lawula yi hlawuriwile kahle, ku ni khombo leri engetelekeke ra cavitation, leswi nga ta endla leswaku ku va ni mpfumawulo lowukulu ni ku rhurhumela, leswi endlaka leswaku ku onhaka hi ku hatlisa swinene tiphayiphi ta le ndzeni ni ta le hansi tavalve.

Ku engetela kwalano, mpfumawulo wale henhla hi ntolovelo wuvanga ku rhurhumela lokunga onhaka tiphayiphi, switirhisiwa na switirhisiwa swin’wanaValvehi ku famba ka nkarhi, ku onhaka ka swiphemu, valve cavitation leyi vangiwaka hi sisiteme ya tiphayiphi leyi talaka ku onhaka swinene. Ku onhaka loku swivangiwa ngopfu hi matimba ya mpfumawulo wa vibration, maendlelo ya corrosion lawa ya hatlisisiweke xikan’we na cavitation leswi kombisiwaka hi levele yale henhla ya mpfumawulo wa vibration ya amplitude leyikulu leyi endliwaka hiku tumbuluxiwa naku wa ka ti steam bubbles ekusuhi nale hansi ka shrinkage.

Hambi leswi leswi hi ntolovelo swi humelelaka eka boloti- valvena ti rotary valves emirini, entiyisweni swinga humelela eka ku vuyelela ko koma, lokukulu loku fanaka na xiphemu xa miri wa wafer xa V-ballvalve, ngopfu-ngopfuti valve ta phaphatanieka tlhelo ra le hansi ra valve lokovalveyi tshikileriwa eka xiyimo xin’we lexi talaka ku va na xiendlakalo xa cavitation, lexi talaka ku vupfa eka tiphayiphi ta valve na ku lunghisa ka welding, valve a yi ringanelanga eka xiphemu lexi xa layini.

Kunga khathariseki leswaku cavitation yihumelela endzeni ka valve kumbe ehansi ka valve, switirhisiwa eka ndzhawu ya cavitation swita onhaka swinene eka ti ultra-thin films, springs na swivumbeko swa cantilever swa xiphemu lexintsongo, ku rhurhumela lokukulu ka amplitude kunga hlohletela oscillations. Tindhawu leti talaka ku tsandzeka ti kumeka eka switirhisiwa swo fana na swipima ntshikelelo, swihundzisi, mavoko ya thermocouple, ti flowmeters, tisisiteme to teka swikombiso Ti actuators, positioners na swiwitsi swa swipimelo leswi nga na swihlovo swi ta xaniseka hi ku hatlisa ku onhaka, naswona ti mounting brackets, fasteners na connectors swi ta ntshunxeka no tsandzeka hikwalaho ka ku rhurhumela.

Fretting corrosion, leyi humelelaka exikarhi ka swilo leswi onhakeke leswinga langutana na ku rhurhumela, switolovelekile ekusuhi na ti cavitation valves. Leswi swihumesa ti hard oxides tani hi ti abrasives ku hatlisisa ku onhaka exikarhi ka swilo leswi onhakeke. Switirhisiwa leswi khumbekaka swikatsa ti isolation na ti check valves, ku engetela eka ti control valves,tipompo, ti rotating screens, samplers na yin’wana na yin’wana yo rhendzeleka kumbe ku rhetela.

Ku rhurhumela ka amplitude yale henhla kunga tlhela ku pandzeka no bola swiphemu swa valve ya nsimbi na marhangu ya tiphayiphi. Swiphemuphemu swa nsimbi leswi hangalakeke kumbe switirhisiwa swa tikhemikhali leswi onhaka swi nga thyakisa swihangalasamahungu eka phayiphi, leswi nga vaka na nkucetelo lowukulu eka tiphayiphi ta valve ta vuhlayiseki na switirhisiwa swa tiphayiphi swa vutengi bya le henhla. Leswi na swona a swi pfumeleriwi.

Ku vhumbha ka ku tsandzeka ka cavitation ka ti plug valves swi rharhanganile swinene naswona a swi hlayeriwanga ntsena ku hunguteka ka ntshikelelo wa choke. Ntokoto wukomba leswaku swinga endleka leswaku ntshikelelo eka nambu lowukulu wuhunguteka kuya eka ntshikelelo wa vapor ya mati loko kungase va na local vaporization ya ndzhawu liya xikan’we naku wa ka steam bubble. Vaendli van’wana va ti valve va vhumbha ku tsandzeka ka ku sirheleriwa ka dyambu ka ha ri emahlweni hi ku hlamusela ku hunguteka ka ntshikelelo wa ku onhaka ko sungula. Ndlela ya muendli wa valve yosungula hiku vhumbha ku onhaka ka cavitation yiseketeriwe eka mhaka ya leswaku ti steam bubbles ta wa, leswi vangaka cavitation na mpfumawulo. Ku kumiwile leswaku ku onhaka lokukulu ka cavitation ku ta papalatiwa loko mpimo wa mpfumawulo lowu hlayiweke wu ri ehansi ka swipimelo leswi xaxametiweke laha hansi.

Vukulu bya valve kuya fika eka 3 inches – 80 dB

Vukulu bya valve bya 4-6 wa ti inches – 85 dB

Vukulu bya valve 8-14 wa ti inches – 90 dB

Vukulu bya ti valve bya 16 inches na ku tlula – 95 dB

Maendlelo yo herisa ku onhaka ka cavitation

Dizayini yo hlawuleka ya valve ku herisa cavitation yi tirhisa ku khuluka loku avaneke na ku hunguteka ka ntshikelelo loku ringanisiweke:

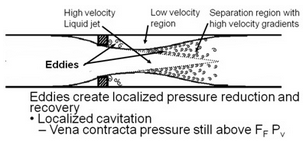

“Valve diversion” i ku avanyisa ku khuluka lokukulu eka ku khuluka ko hlayanyana lokuntsongo, naswona ndlela yo khuluka ya valve yi endliwile leswaku ku khuluka ku khuluka hi nhlayo ya swivulwa leswintsongo leswi fambelanaka. Tanihi leswi xiphemu xa vukulu bya cavitation bubble xi hlayiwaka hi ku pfuleka loku ku khuluka ku hundzaka eka kona. Ku pfuleka lokuntsongo ku endla leswaku kuva na swiphemuphemu leswintsongo, leswi endlaka leswaku kuva na mpfumawulo wutsongo naswona ku onhaka kutsongo loko swita eka ku onhaka.

“Ku hunguteka ka ntshikelelo loku ringanisiweke” swi vula leswaku valve yi endleriwe ku va ni tindhawu timbirhi kumbe ku tlula to lulamisa hi ku landzelelana, hikwalaho ematshan’weni ya ku hunguteka hinkwako ka ntshikelelo hi goza rin’we, yi teka magoza yo hlayanyana lamatsongo. Kuhunguteka ka ntshikelelo wa munhu hi xiyexe swinga sivela ntshikelelo eka shrinkage kuva wu wa ntshikelelo wa vapor wa mati, xisweswo ku herisa xiendlakalo xa cavitation eka valve.

Ku hlanganisiwa ka diverting na pressure drop staging eka valve yin’we swipfumelela ku antswisiwa ka cavitation resistance hi. Hi nkarhi wa ku cinciwa ka valve, ku veka valve yo lawula xikan’we na ntshikelelo eka ndzhawu yo nghena ya valve swile henhla (xikombiso, tlhelo rale kule rale henhla, kumbe eka ku tlakuka kale hansi), minkarhi yin’wana leswi herisaka swiphiqo swa cavitation.

Ku engetela kwalano, ku veka valve yo lawula eka ndzhawu ya mahiselo ya mati, naswona hikokwalaho ka sweswo ntshikelelo wale hansi wa vapor (kufana na mahiselo yale hansi ya side heat exchanger) swinga pfuneta ku herisa swiphiqo swa cavitation.

Nkatsakanyo wu kombisile leswaku xiendlakalo xa cavitation xa ti valve hakunene a hi ntsena mayelana na matirhelo ya ku onhaka na ku onhaka ka ti valve. Tiphayiphi ta le hansi na switirhisiwa na swona swi le khombyeni. Ku vhumbha cavitation na ku teka magoza yo yi herisa hi yona ntsena ndlela yo papalata xiphiqo xa ku durha ka tihakelo ta ku tirhisiwa ka valve.

Nkarhi wa poso: Jun-25-2023